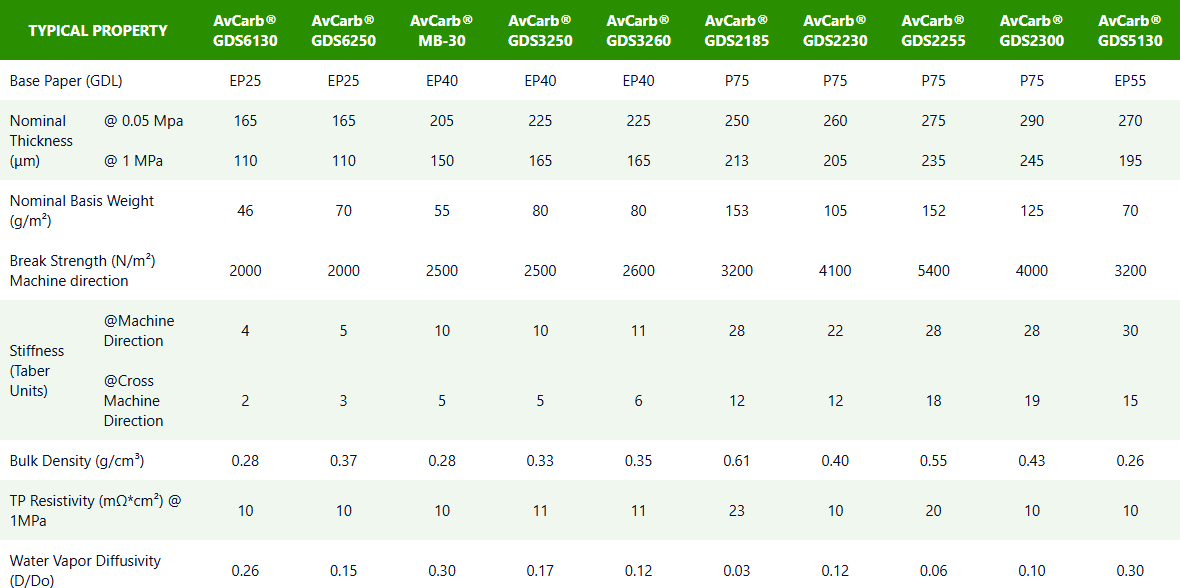

AvCarb’s Gas Diffusion Systems incorporate a hydrophobically treated AvCarb GDL, and a surface coated microporous layer, optimized for specific fuel cell construction and operating requirements. The designs are based upon 25 years of collaboration with world leading fuel cell manufacturers and span the full range of today’s operating environments. AvCarb’s best in class quality and manufacturing flexibility provides the best customer value minimizing manufacturing scrap and costly re-builds due to low performing cells and providing best in class durability with GDL performance shown for over 38,000 hours of continuous operation in some systems

| TYPICAL PROPERTY | AvCarb® EP40 | AvCarb® P75 | AvCarb® EP55 | AvCarb® EP25 |

|---|---|---|---|---|

| Nominal Thickness (μm) (@ 5.0 N/cm²) | 184 | 232 | 262 | 140 |

| Nominal Basis Weight (g/m²) | 36 | 71 | 51 | 27 |

| Break Strength (N/m) Machine direction | 1500 | 2100 | 2300 | 1700 |

| Stiffness (Taber Units) Machine direction | 9.0 | 24.0 | 27.0 | 4.0 |

| Bulk Density (g/cm³) (@ 0.69 N/cm²) | 0.19 | 0.30 | 0.20 | 0.19 |

| Through-Plane Air Permeability (Gurley sec/100 cc) | 4.0 | 15.0 | 5.0 | 5.0 |

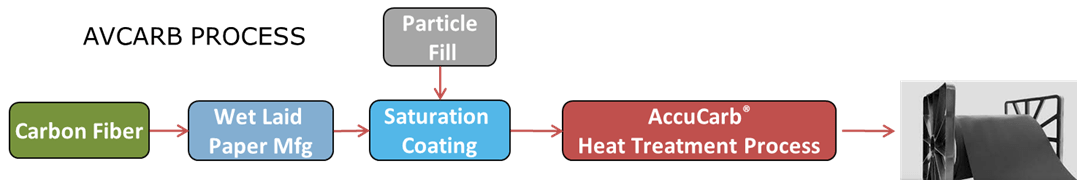

AvCarb Process combines high quality with product flexibility and continuous improvement:

- Stronger, Smoother MPL designs

- Customizable Mechanical Properties

- PFAs Free Substrate & MPLs

- Widest & Longest Continuous Webs in the Industry

Gas Diffusion Systems (GDS)

AvCarb’s Gas Diffusion Layer papers are manufactured through a complex multi-step process that utilizes carbon fiber and a proprietary saturation ink that allows for optimal down-web and cross-web uniformity and most consistent performance. By altering the composition and loading of the saturation ink, the internal structure of the paper can be modified allowing papers to shift critical properties such as diffusivity, conductivity, mechanical strength, porosity, pore size, etc. By creating different structures with the same process and raw materials, the manufacturing cost is lower as customers get the benefit of volume production with different designs. AvCarb’s best in class quality and manufacturing flexibility provides the best customer value minimizing manufacturing scrap and costly re-builds due to low performing cells and providing best in class durability with GDL performance shown for over 38,000 hours of continuous operation in some systems.

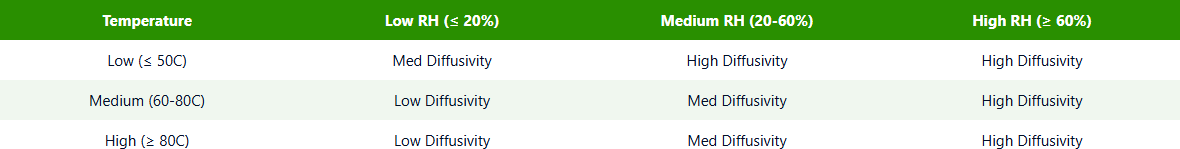

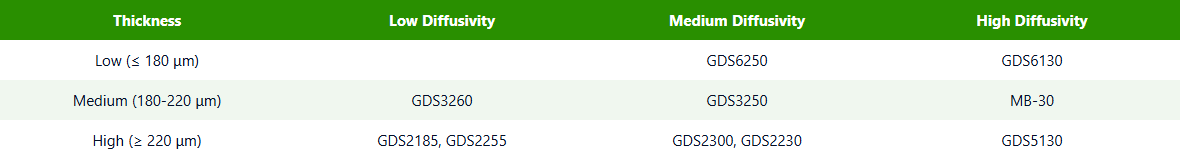

GDS Selection Guide

Use the table to determine the diffusivity level of the GDL required for your application. Based on the target thickness under compression, match the diffusivity level to determine the best GDL for your application.

| Temperature | Low RH (≤ 20%) | Medium RH (20-60%) | High RH (≥ 60%) |

| Low (≤ 50C) | Med Diffusivity | High Diffusivity | High Diffusivity |

| Medium (60-80C) | Low Diffusivity | Med Diffusivity | High Diffusivity |

| High (≥ 80C) | Low Diffusivity | Med Diffusivity | High Diffusivity |

| Thickness | Low Diffusivity | Medium Diffusivity | High Diffusivity |

| Low (≤ 180 μm) | GDS6250 | GDS6130 | |

| Medium (180-220 μm) | GDS3260 | GDS3250 | MB-30 |

| High (≥ 220 μm) | GDS2185, GDS2255 | GDS2300, GDS2230 | GDS5130 |

Special Considerations

For highest operating current densities (>2 A/cm²) always choose a high diffusivity material

For membrane thickness ≤ 10 microns choose a smooth MPL version (replace 2nd digit in product code with a 9 – e.g., GDS6950, GDS2930, MB-39, etc.)

Asymmetric GDL combinations (e.g., different anode and cathode designs) often provide optimal performance, but are more complicated to process. Please contact an expert to discuss your needs.